Choosing the correct gas detector (fixed)

There is a wide range of fixed gas detection equipment, and while many may appear similar at first glance, upon closer inspection, each device boasts distinct functionalities and features, providing unique advantages. It’s crucial to identify your specific requirements before deciding on the most suitable gas detector for your needs.

The key purpose of a fixed gas detector is their ability to alert operators employers and employees to potentially life-threatening and premise damaging hazards. Therefore, the selection of a gas detector should never be taken lightly.

Determine the primary goal

The first step when searching for a fixed gas detection solution involves clarifying the objective. Once the objective is defined, you should have a clearer understanding of what equipment is required. For example:

- 1) Health and wellbeing of site personnel and safety of the building

- 2) Ensure compliance with legal regulations

- 3) Meet the specific requirements set by insurers

Identify the gases you need to detect

Identify the gases requiring detection and their potential hazards. A well-suited gas detection solution will effectively identify specific gases and prompt warnings prior to reaching hazardous concentration levels.

Once this information is acquired, the following steps should be taken:

STEP 1

Recognise the types of risks present (flammable, toxic, and/or asphyxiant gases) to determine suitable sensor types.

STEP 2

Define the critical concentration levels that could pose danger to establish alarm thresholds, sensor placement for fixed gas detection systems, etc.

STEP 3

Identify potential sources of gas leaks to determine the quantity and placement of sensors needed for a fixed gas detection system. Alternatively, if leak sources are unknown, utilising portable gas detectors is advisable. Portable Gas Detectors | Detect Toxic Gases | Rockall Safety

What we recommend

Honeywell Sensepoint XCD Fixed Gas Detector

The Honeywell Sensepoint XCD is a fixed-point gas detector and transmitter that is used to monitor combustible, toxic, and oxygen gas hazards in potentially explosive atmospheres. It is available in three versions: flammable, oxygen, and toxic.

The Honeywell Sensepoint XCD is a fixed-point gas detector and transmitter that is used to monitor combustible, toxic, and oxygen gas hazards in potentially explosive atmospheres. It is available in three versions: flammable, oxygen, and toxic.

The flammable version of the Sensepoint XCD uses a catalytic sensor to detect flammable gases in the range of 0 to 100%LEL (lower explosive limit). The infrared (IR) sensor version is available for the detection of methane in the range of 0 to 100%LEL, propane (with cross-sensitivities to ethylene and butane), and carbon dioxide (CO2) in the range of 0 to 2.00 %v/v.

The oxygen version of the XCD uses an electrochemical cell (EC) sensor to measure oxygen deficiency and enrichment in the range of 0 to 25 %V/V.

The toxic version of the XCD uses EC sensors to detect carbon monoxide (CO), hydrogen sulphide (H2S), nitrogen dioxide (NO2), and hydrogen (H2).

The XCD transmitter is a rugged, weatherproof unit that is designed for use in hazardous areas. It has a built-in LCD display that shows the current gas concentration, alarm status, and battery life. The transmitter can also be configured and controlled using a magnet switch.

Honeywell Sensepoint XCD Fixed Gas Detector | Rockall Safety

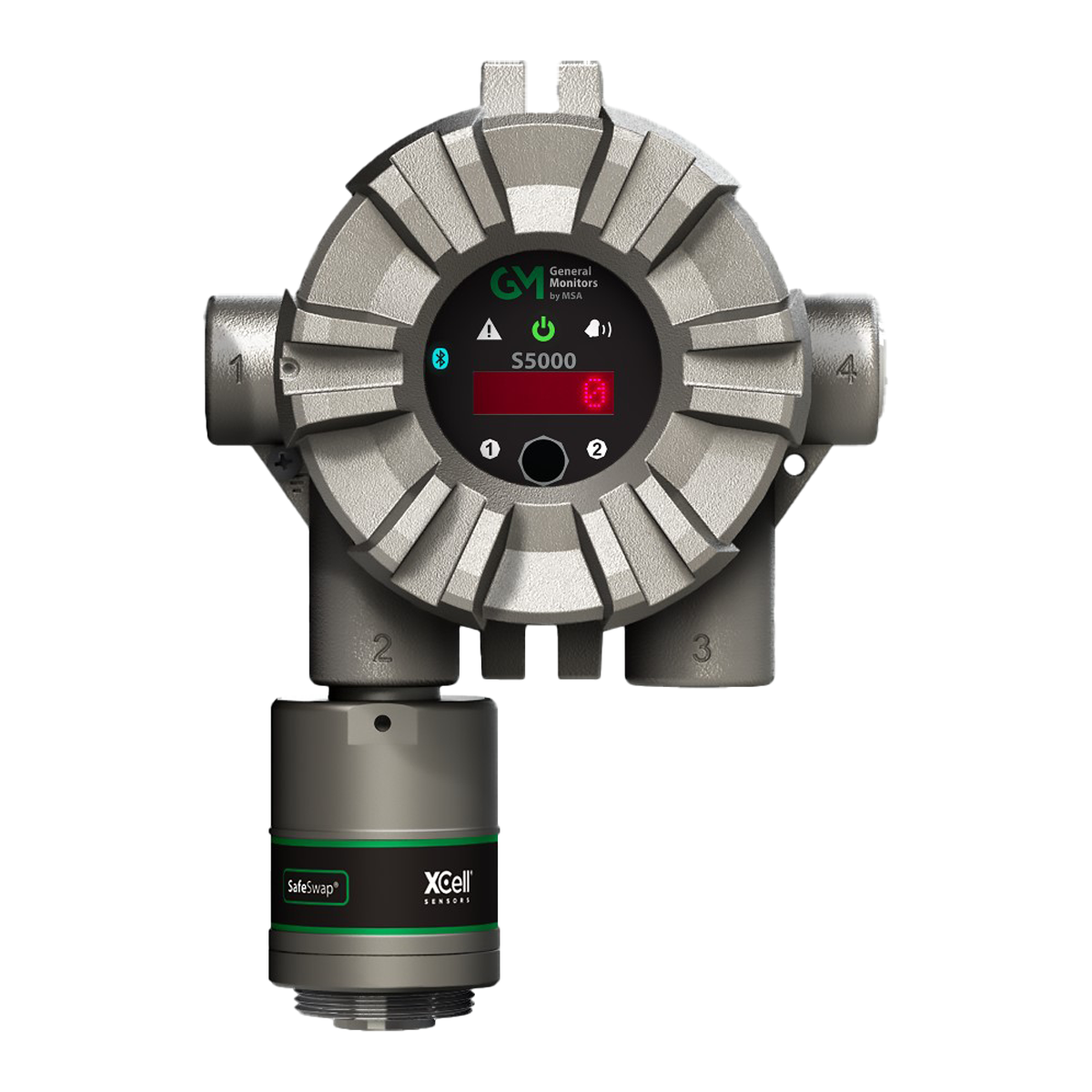

MSA General Monitors S5000 Gas Monitor

The MSA General Monitors S5000 Gas Monitor is a highly advanced gas detector suitable for extreme environments, capable of detecting oxygen, toxic, and combustible gases. It utilises breakthrough XCell® gas sensors with TruCal® technology, extending calibration cycles up to 24 months and actively monitoring sensor integrity. TruCal* ensures worry-free operation by compensating for environmental factors causing sensor drift and automatically self-checking four times a day, reducing downtime.

An industry-first Diffusion Supervision feature warns of sensor inlet blockages, ensuring continuous gas detection. The device operates in wide temperature ranges (-55°C to +75°C) and offers Bluetooth wireless technology for mobile device connectivity via the X/S Connect App, enhancing real-time monitoring and control capabilities.

Dual sensor capability provides increased sensing power with minimal footprint, while SafeSwap enables safe and quick sensor replacement without instrument shutdown. The device features intuitive touch-button or magnetic interface, identical footprint and wiring to previous models for simple retrofits, and cloud connectivity options with FieldServer ProtoAir FGFD Gateway.

*TruCal available on H2S and CO digital sensors only.

MSA General Monitors S5000 Gas Monitor | Rockall Safety

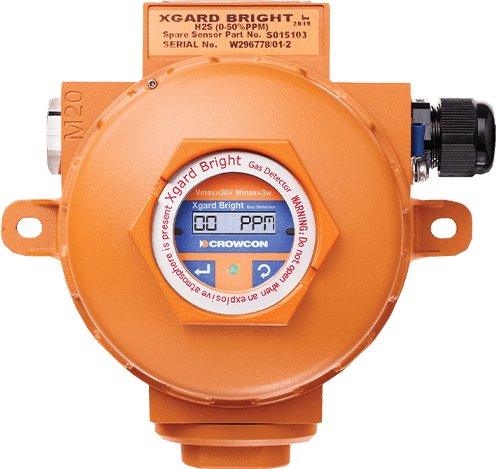

Crowcon Xgard Bright Fixed System

The Xgard Bright is a versatile gas detection system designed for detecting flammable and toxic gases and monitoring oxygen levels. It offers ease of operation and reduced installation costs.

Standard features include analogue 4-20mA and RS-485 Modbus signals, along with an Alarm and Fault relay. Optional HART communications are also available.

Its 4-wire addressable implementation significantly reduces cabling requirements. The large OLED display enables easy operation during installation, calibration, and routine maintenance without the need to open the housing.

Crowcon Xgard Bright Fixed System | Rockall Safety

View all of our fixed gas detectors here: Fixed Gas Detectors | Fixed Gas Detection Systems (rockallsafety.co.uk)

For more information on choosing the correct gas detector for your company’s needs, call our team at 02920 759683.

Written by Rhys Redrup